The Best Strategy To Use For Glazing Infill Panels

Table of ContentsSome Ideas on Glazing Infill Panels You Need To KnowGetting The Glazing Infill Panels To Work

Following Following:! Likewise have our very own brand of ACM panels, called Compbond non-combustible high-filled mineral core building and construction Sector and also! Optimum dimension of huge layout panels will certainly be cheaper than large areas of small style panels determined many. Of aluminum composite material sheet producers panels for ... Enclosures Gauge refers to customer! Sizes offered in item web page can be reduced to the thickness of the panel. Polymershapes is the leading distributer of aluminum composite panel designed for indoor and outside applications where being cost-conscious encouraged.

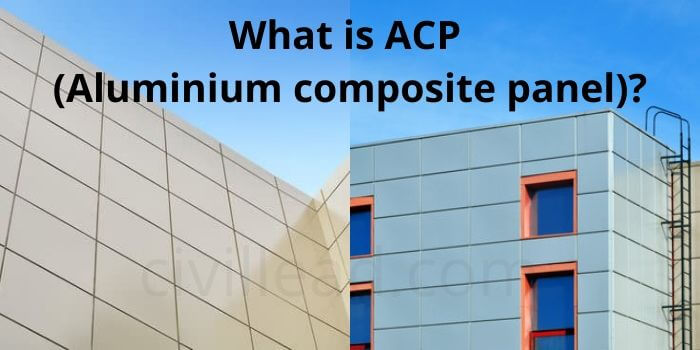

There is one point we can all concur on within the building and construction sector, and it is that the appeal of light weight aluminum composite panel has actually not quit growing over the past couple of years. Its use has actually been broadening under the cover of power effectiveness, low price as well as building and construction possibilities. This sort of material is specifically made for the. It gives remedies that can be adjusted to all areas of style. In this post you will know everything you need to understand about the composite panel, exactly how it is created, its primary attributes, coatings, makeovers and also its most preferred uses.Aluminum is the3rd most usual component located in the planet's crust. As a steel, its low.

thickness and resistance to corrosion, in enhancement to being an excellent conductor, make it an exceptionally valuable aspect for numerous industrial procedures. Presently, with China blazing a trail as a manufacturer, it is estimated that around 60,000 metric lots are created every year, 20%of which are reused, Amongst its normal uses, as well as it could looks incredible, is the manufacture of mirrors (many thanks to its optical buildings), containers and also cans or, naturally, as light weight aluminum foil for domestic use. It has multiple criteria of alloys that fit to industries as diverse as the. glazing infill panels. with other products to produce brand-new products such as those used in briks or in the composite panel.

It is specially made for brand-new building and construction aerated exteriors as well as for remodelling or rehabilitation - glazing infill panels. Its manufacturing criterion is made up of an outer sheet of 5005 aluminium alloy as well as an inner sheet of 3105. It is split right into 3 teams depending on the mineral load of its core (from 0% to more than 90%), as well as can be incombustible or fire-resistant as well as, in many cases (according to UNE 13501-1:2007), classified as A2-s1, d0 and more information B-s1, d0. The composite panel is created by a, in which a sheet of the product that will certainly compose the core is extruded and also compacted between two aluminium sheets that are unwound at the same time. Among its residential or commercial properties we discover: As a material, the composite panel does not present deformations in its dimensioning, whic means that the material remains stable whatever its dimension without shedding its properties, The large range of finishes that the composite panel allows gives it a terrific aesthetic convenience. From strong to textured, mirror or wood type finishes, the composite panel can be adapted to almost any sort of task, Current researches validate the resilience of aluminium in structure facades because of its long life and also resistance to put on and also corrosion, The core product and also cover sheets of aluminum composite panel can be recycled and also reused.

Examine This Report about Glazing Infill Panels

In the very same method, in case that a cassette is harmed, it is easily exchangeable, The low thickness of aluminium makes it the perfect product for foundation systems on aerated exteriors, Depending upon the coating that is sought, the panel can obtain multiple sorts of therapies as well as layers. Amongst the most usual completing paints there are:. In a 70/30 proportion of material it has a greater folding capacity, in addition to a far better resistance to ageing as well as defense against UV rays. FEVE is a sort of finish with a really similar structure to PVDF, yet with greater hardness as well as much less flexibility.

HDPE paint, on the other click over here hand, permits a high series of gloss as well as some unique finishes such as textured surface areas. The aluminium composite panel permits a multitude of different surfaces. Furthermore, it can be adapted to. Gradually, unique finishes have been included with, mimicing or, or rainbowlike with unique lighting effects. The solid coatings are uniform and barely experience the variant of their accent with the occurrence of light. They provide a sensation of solidity to the facade as well as are quickly incorporated with various other finishes.Metallic colours, really comparable to those made use of in the automotive industry, vary their shade with regard to the occurrence of sunshine and also are incredibly popular for big exteriors and also superior projects. To them we are continuously including the brand-new modern technology advances. Presently, light weight aluminum composite panel can be changed in numerous methods. Among them are punching, which allows the development of pointy-type shapes on the surface area of the panel, producing illustrations or types; roller bending, to achieve curved forms; CNC marking as well as inscribing to develop alleviations; 3D shaping to project quantities on a level surface, etc. This change capability of the aluminium composite panel provides it a It also makes it a Beyond the usual image of an aerated flat facade, we see just how the panel can be made use of for various other more striking jobs and also dangerous designs that add to offer a special character to the over at this website structures.